Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: Outer Diameter(Round):60~1420mm Thickness:2.5~3.7mm

Brand: ChengYuan

Type: Seamless

Certification: API

Application: Boiler Pipe

Section Shape: Round

Surface Treatment: Varnishing

Usage: Special Purpose

Technique: ERW

Material: Carbon Steel

Packaging: Plastic caps on both ends,Steel bundle

Productivity: 120000 Tons

Transportation: Ocean,Land,Air

Place of Origin: Hebei,

Supply Ability: 10000 Tons

Certificate: ISO9001

HS Code: 73049000

Port: Tianjin Xingang,Dalian,Qingdao

Payment Type: L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIP

10 Inch 14 Inch Schedule 40 Carbon Pipe

Hebei Chengyuan Management Group Co., Ltd.

It is mainly used to manufacture bridges, ships, vehicles, boilers, high pressure vessels, oil and gas pipelines, large steel structures, etc. Performance Requirements (1) High Strength: Generally its yield strength is over 300 MPa. 2) High toughness: the elongation is required to be 15%-20%, and the impact toughness at room temperature is greater than 600 kJ/m-800kJ/m. For large welded components, higher fracture toughness is also required. 3) Good welding and cold forming properties. 4) Low cold-brittle transition temperature. 5) Good corrosion resistance. Composition characteristics (1) Low carbon: due to the high requirements of toughness, weldability and cold forming properties, its carbon content does not exceed 0.20%. 2) Addition of manganese-based alloying elements. 3) Addition of niobium, titanium or vanadium as auxiliary elements: a small amount of niobium, titanium or vanadium forms fine carbides or carbonitrides in steel, which is conducive to obtaining fine ferrite grains and improving the strength and toughness of steel. In addition, adding a small amount of copper (< 0.4%) and phosphorus (about 0.1%) can improve the corrosion resistance. Adding a small amount of rare earth elements can desulfurize and degasse, purify steel, improve toughness and process performance. Heat treatment characteristics This kind of steel is generally used in hot-rolled air-cooled state without special heat treatment. Ferritic sorbite is commonly used.

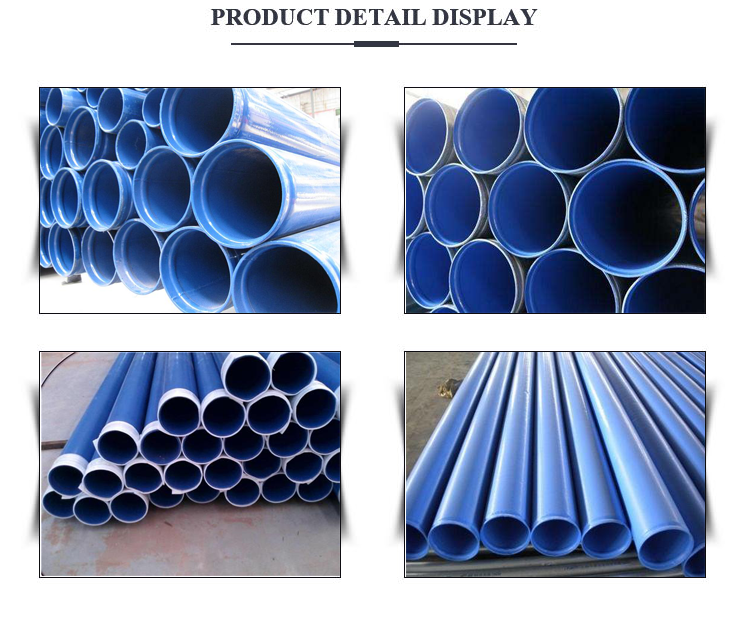

Product Categories : Plastic Coated Composite Pipe

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.